Watches and metal conflict parts

In watch manufacturing, the stamping process is often referred to as Fine Blanking, as it requires a precision level that is typically at the micrometer scale (0.001mm), far exceeding that of ordinary hardware components.

The following are the specific roles and application scenarios of metal stamping parts in the watch industry:

1. Dial&Hands - The Core of Beauty

This is the most intuitive manifestation of stamping technology.

Dial Base:

Function: The "face" of the watch.

Craftsmanship: The dial is usually made of a piece of brass, which is cut into circular pieces through a stamping die, and the center hole for installing the pointer and the positioning hole for installing the scale are punched out.

The complex "radial patterns" or "grid patterns" on the dials of many mid to low end watches are not expensive hand carved, but are produced using high-precision embossing.

Hands:

Function: Indicate time.

Craftsmanship: Watch hands are extremely thin and have complex shapes (such as willow needles, Breguet needles). They are precision stamped from thin metal sheets.

Stereoscopic feeling: There will be ridges in the middle of the high-end pointer, which is also a three-dimensional shape formed by the extrusion of the mold at the moment of stamping.

2. Case & Case Back

Although high-end watch cases often use CNC cutting, stamping is indispensable in blank forming and back cover manufacturing.

Case Blanks:

Function: Reduce waste of expensive metals such as gold and 904L steel.

Process: First, use thick plate stamping (or cold forging) to produce a "blank" that is close to the shape of the watch case, and then perform fine CNC machining. This saves a lot of material compared to cutting directly from solid bar material.

Case Back:

Function: Seal the back of the watch.

Process: Especially the press in back cover (commonly seen in quartz watches), which is a bowl shaped structure completely formed by stamping. Even for spiral back covers, their initial shape is stamped out.

3. Bracelet&Clasp - the most complex stamping parts in terms of structure

The comfort and opening and closing feel of a metal strap depend entirely on the design of the stamped parts.

Deployant Clasp:

Function: It is commonly referred to as a "butterfly clasp" or "folding clasp".

Craftsmanship: This is a precision mechanical structure assembled from multiple stainless steel stamped sheets, springs, and pins. Stamped parts must have excellent elasticity (for the "click" sound during locking) and wear resistance.

Links:

Hollow strap: The strap of old-fashioned or cheap watches is "rolled", which means that a thin steel sheet is stamped and rolled into a section, which is a pure stamping process.

Solid strap: The solid strap section of modern watches is usually stamped out first, and then drilled and polished.

4. Movement Parts - the pinnacle of precision

This is where the "precision punching" technology shines brightly. The internal space of the movement is extremely small, with a large number of parts.

Mainplate & Bridges:

Function: The "foundation" that supports all gears.

Process: In mass-produced movements, the initial contour and partial grooves of the substrate are completed through stamping to improve production efficiency.

Date Disc:

The thin metal ring printed with numbers 1-31 is a typical precision stamped part.

Battery Contacts:

The conductive metal sheet in quartz watches is usually stamped and gold-plated from phosphor copper.

Levers & Springs:

Function: Control the start, stop, and reset of the timing function.

Craftsmanship: These parts have extremely irregular shapes and require specific elasticity. Wire cutting is too slow, precision punching is the best choice. Precision punching can ensure that the edges of the parts are bright and tear free, and can be assembled directly without the need for secondary polishing.

5. Sealing and fixing components

Movement Holder:

Function: Fix the movement inside the case to prevent it from shaking.

Process: Usually a stamped metal or plastic ring (but in anti magnetic watches, it must be a soft iron stamped part).

Anti magnetic inner cover:

In pilot watches, in order to prevent magnetism, a soft iron shell is wrapped around the movement, which is a deep drawn stamped part.

Why does the watch industry need stamping?

Material Cost:

Watches commonly use precious metals such as 18K gold and platinum. Cutting processing will turn a large amount of gold into debris (although recyclable but with losses), while stamping can preserve materials to the greatest extent possible, saving materials means saving money.

Micro-Precision:

Fine Blanking can punch holes with a diameter of 0.1mm on parts with a thickness of only 0.5mm, and the cross-sectional smoothness is extremely high, which is crucial for the coordination of movement parts.

Consistency in mass production:

Brands like Swatch or Casio produce millions of watches annually. Only stamping molds can ensure that the first gear and the one millionth gear are exactly the same, ensuring accurate timing.

summary

In the watch industry, the role of metal stamping parts can be divided into two categories:

Externally: it is the mechanical skeleton of the clasp, the delicate face of the dial, endowing the watch with beauty and wearability.

Internally, it is a precision component of the movement that achieves industrialized high-precision operation in the microscopic world through "precision punching" technology.

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

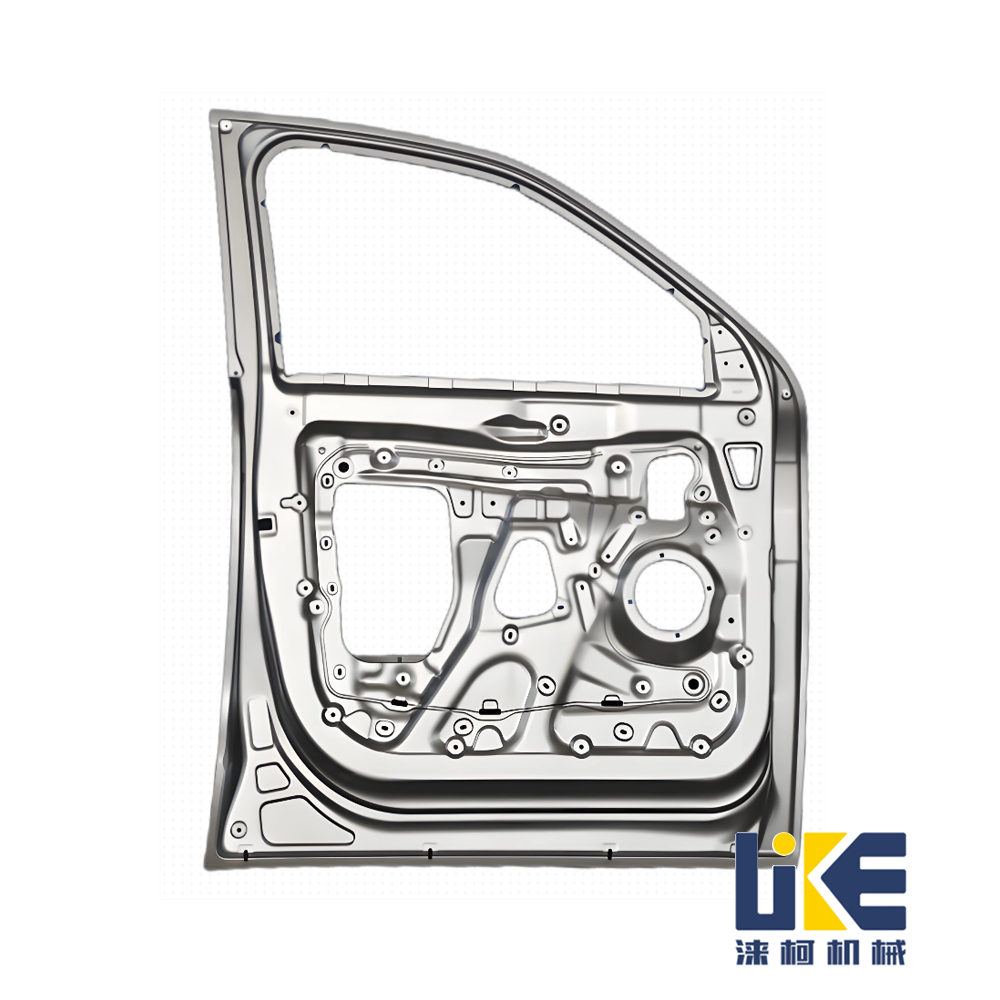

Automotive and metal stamping parts

Automotive and metal stamping parts

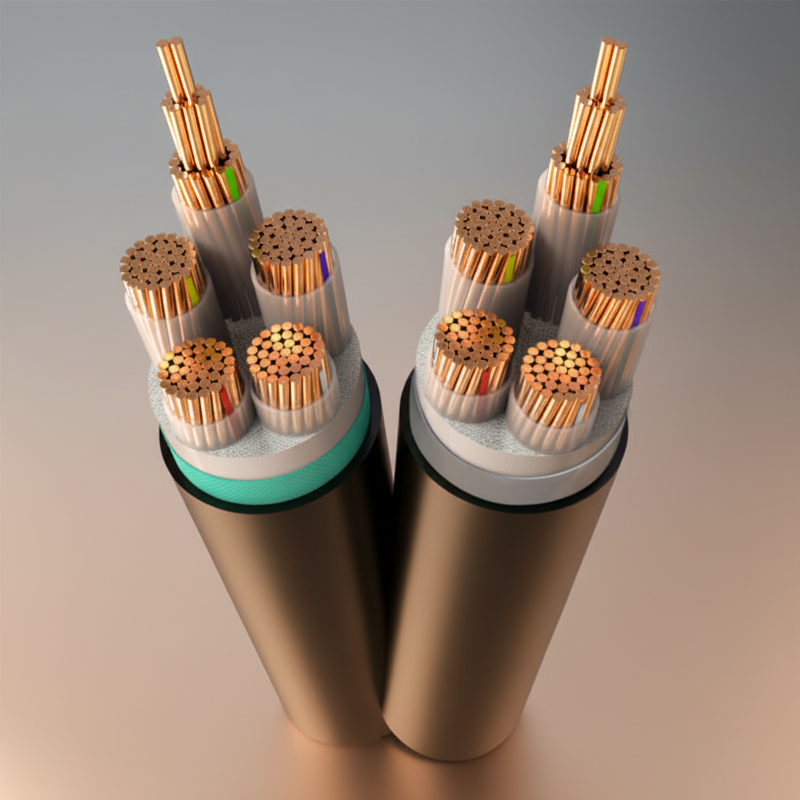

Cables and metal stamping parts

Cables and metal stamping parts

Numerical control equipment and metal stamping parts

Numerical control equipment and metal stamping parts